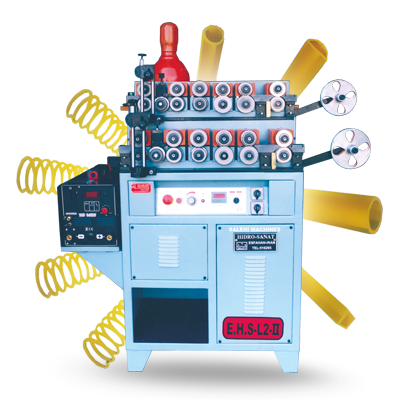

Description

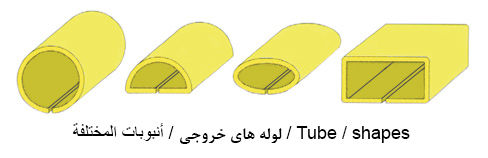

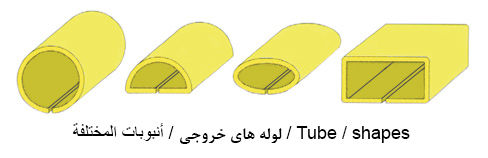

These profiling machines make welded and un welded tubes out of flat metal strip. Tubes are round, square, rectangular and TV-shaped, or have special profiles (available on request).

The profiling process uses several rollers and guides that are easily and quickly replaced. The first station has a shearing unit for strip calibration.

An automatic T.I.G welding process (without filler material) at the end of the cycle ensures uniformity and maximum mechanical strength of the tubes.

Automatic welding is included in the below models and supplied on customer’s request .

the work area is protected by a special transparent safety panel and has its own lighting.

Available on request a wheeled stand and the TIG welding unit or Oxygen and Gas Welding Unit and manometer.

Models;

» Profile L1

(Making Profiling diameter: 2 – 6 mm)

» Profile L2 ( Single Head)

(Making Profiling diameter: 2.5 – 10 mm)

» Profile L2 ( Double Head)

(Making Profiling diameter: 2.5 –10 mm)

This model has two gearboxes and two separated motors. The ability of setting more than one fixed output and two sizes of tubes out is available of two roof profiling machines.

» Profile L3 ( For all types of Hollow chains)

(Making Profiling diameter: 3 – 10 mm)

» Profile L4

(Making Profiling diameter: 3 – 12 mm)

Specification

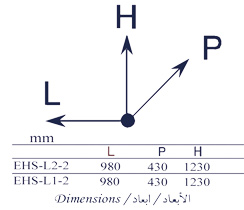

Model:

L1-L2

Roller wheelbase

55mm-65mm

Pair of rollers

6mm

Profiling diameter

1/5:6mm-1/5:12mm

Profiling speed

0/5:4mm-0/5:8mm

Voltage

220/380V - 50/60Hz

Power unstalled

0.75kW

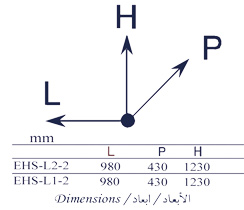

Width

980mm

Depth

430mm

Height

1230mm

Weight

500Kg

TIG Welding system

OK

These profiling machines make welded and un welded tubes out of flat metal strip. Tubes are round, square, rectangular and TV-shaped, or have special profiles (available on request).

The profiling process uses several rollers and guides that are easily and quickly replaced. The first station has a shearing unit for strip calibration.

An automatic T.I.G welding process (without filler material) at the end of the cycle ensures uniformity and maximum mechanical strength of the tubes.

Automatic welding is included in the below models and supplied on customer’s request .

the work area is protected by a special transparent safety panel and has its own lighting.

Available on request a wheeled stand and the TIG welding unit or Oxygen and Gas Welding Unit and manometer.

Models;

» Profile L1

(Making Profiling diameter: 2 – 6 mm)

» Profile L2 ( Single Head)

(Making Profiling diameter: 2.5 – 10 mm)

» Profile L2 ( Double Head)

(Making Profiling diameter: 2.5 –10 mm)

This model has two gearboxes and two separated motors. The ability of setting more than one fixed output and two sizes of tubes out is available of two roof profiling machines.

» Profile L3 ( For all types of Hollow chains)

(Making Profiling diameter: 3 – 10 mm)

» Profile L4

(Making Profiling diameter: 3 – 12 mm)

Model:

L1-L2

Roller wheelbase

55mm-65mm

Pair of rollers

6mm

Profiling diameter

1/5:6mm-1/5:12mm

Profiling speed

0/5:4mm-0/5:8mm

Voltage

220/380V - 50/60Hz

Power unstalled

0.75kW

Width

980mm

Depth

430mm

Height

1230mm

Weight

500Kg

TIG Welding system

OK